I have always spent a considerable amount of time doing the graphics and trim schemes on my airplanes. I’ve read magazine articles and watched you tube videos about ways that other folks do these processes. This is one method I have learned that is a great time saver. It is most useful when your graphic contains several pieces that all need to be applied in correct relation to each other. I will use a recent repair on my “KWIKI” sport plane for the example. It started with some damage to the top wing covering. I cut away the affected areas and replaced the covering there. Now I am ready to re-do the graphics.

These are the materials you will need for the project;

- Windex glass cleaner with a mister or spray bottle to apply

- Sheet of plate glass ($2 at your home improvement center)

- Glad brand “Press’n Seal” (grocery store)

- Your graphic printed on ordinary typing paper

- A sharp exacto or break-away knife

- Your Monokote colors

- Masking tape

- Paper towels

- Squeegee or old credit card

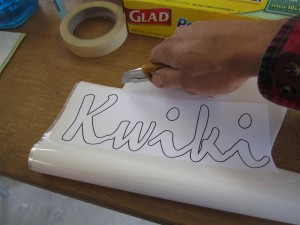

Start by cutting a piece of Monokote just slightly larger than the paper your graphic is printed on. Clean your glass sheet with Windex until it is spotless.

Remove the backing from the Monokote, spray a coat of Windex on the glass, and squeegee the Monokote in place. An old credit card works well for this. Squeegee out as much of the Windex as possible. The idea is to get the Monokote really tight to the glass. Wipe up the excess Windex with a paper towel, and dry the surface well so masking tape will stick. Squeegee and dry again, if necessary.

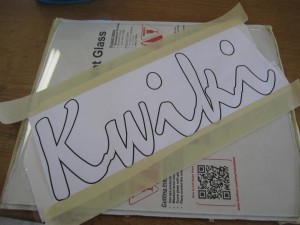

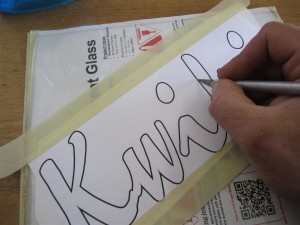

Center the paper print-out over the Monokote, and tape it down. Begin to cut each line. Make sure that your cuts are connected. A sharp blade is critical here. Plan your cuts so that important parts of the template are not removed. If the paper tries to bunch up in front of the blade, either the blade is dull or else you are holding it at too steep of an angle. Try not to lift the blade during long lines or curves. Turn the glass sheet with your other hand, and continue the cut without lifting the blade. You will get smoother lines this way. With practice and experimenting, you will come up with techniques that work for you.

Once you are finished cutting, remove the tape and template. Then carefully remove the scrap Monokote surrounding your graphic. Be prepared to cut any little remaining sections to free the scrap without lifting the graphic. Use a little patience here. It should come out like this…

Tear off a piece of Press’n Seal larger than the graphic. Place it over the graphic, and smooth it out with your hand. Then carefully burnish it down onto each section of the graphic with a thumb or finger. This adheres it to the Monokote. You will see the texture smoothing out as you burnish it down. The idea is to get it adhered to the Monokote every where so that you can lift the whole graphic off of the glass in one sheet. This process is similar to the one used in cut vinyl graphics.

Now clean the surface of the aircraft where you intend to apply the graphic. If it is a fuel powered aircraft, I like to use acetone or some solvent that will remove all traces of oil. Carefully pull the Press’n Seal from the glass sheet, making sure that the graphic comes with it. Burnish edges as needed to get each piece of the graphic started.

Locate the graphic on the surface it is to be applied to. Smooth it out, and make sure the alignment is where you want it. Using an iron set on low (about 200°) tack the graphic to the aircraft. Pay attention to the edges; you need them to be adhered enough that you can pull off the Press’n Seal, but you don’t want to get the Press’n Seal too hot.

When you have it all tacked down, slowly pull off the Press’n Seal. Use the iron to tack down any edges that still try to come up. Take your time. Once the Press’n Seal is removed, go over the graphic again with the iron set a little warmer (perhaps 250°). You will notice some gummy residue from the Press’n Seal adhesive. Clean this off now with acetone or other solvent. Also clean the shoe on the iron. Then seal the graphic down with a hot iron (300° – 325°). Again, pay attention to the edges, especially if it is a fueled airplane. Small wrinkles should shrink out at this time.

And here it is…

The opportunities are fairly endless. If you are patient, you can create intricate designs with this method. For a simple, one piece design you might want to use the Windex/sheet glass cutting method, but you won’t need the Press’n Seal.

A few more pictures of graphics that I have done this way…

There are some more tricks in the bag, but that’s it for today. I hope I’ve inspired you to do some creative graphic designs on your sport model. If you like the tips, feel free to like or share this page on facebook. Until next time, fly it low, inverted, and keep it out of the dirt!